Nearly all cars these days have front disc brakes. Front brakes usually wear out more quickly than the rear brakes (which could either be disc or drum brakes), so they need to be changed more often. You need to change brake pads when they get too thin, especially if they begin to make a persistent metallic squeaking or grinding noise when you press the brake pedal. But noise alone isn't always the best indicator, so it's best to anticipate when this will happen by periodically inspecting the thickness of the brake pads.

Note: If the front end of the car vibrates when you apply the brakes, your brake rotors may be warped. If the rotors appear grooved or uneven, they may be scored. In either case the rotors may also need to be replaced or "turned" on a brake lathe, a procedure not covered here. You may need a professional's help for this, but you can see what's involved in a rotor change by looking here.

Money saved: About $250 for most cars and much more for luxury or performance cars

Time Required: 1 hour

Tools Required

- Disposable mechanic's gloves to protect your hands and keep them clean

- Jack and jack stands

- Lug wrench

- C-clamp or length of wood to retract the piston

- Wrench (choose a socket, open end or adjustable wrench)

- Turkey baster for drawing out brake fluid

- Plastic tie, bungee cord or piece of string

- New brake pads. Since you are saving money by doing this yourself, you might want to consider splurging a bit by buying original manufacturer brake pads, which are more expensive.

- Can of brake fluid — check your owner's manual for the proper type.

Know your calipers: The majority of cars have a "sliding caliper" brake assembly. That's what's shown in the photo above. Compare this brake assembly to the one in your car. Other cars have "fixed caliper" assemblies. The pads in fixed-caliper brakes are also easy to change but the process is slightly different, so we'll cover it in another instructional piece.

Do one side, then the other: For reasons that will be clear later, you should change the pads on one side of the car from start to finish before doing the other side. Also, since you're doing one side at a time, turn the steering wheel so that the wheel you're working on is angled out for better access to the brakes.

Now we can get started.

1. Loosen the lug nuts on the wheel. Then jack up the car and place a jack stand under the car's frame. Lower the jack so its weight rests on the jack stand. Fully remove the lug nuts and remove the wheel. You now have access to the brake assembly and can safely reach under the car.

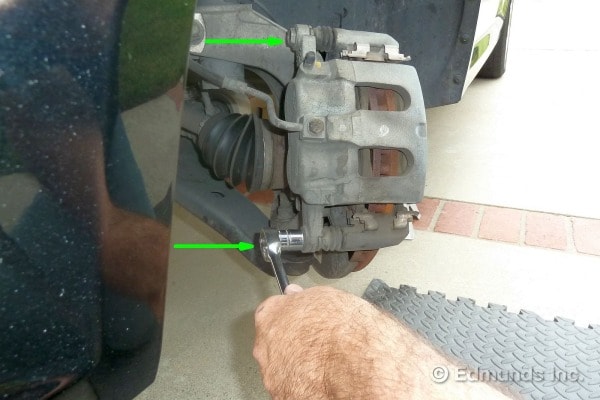

2. Find the two slider bolts (sometimes called "pins") that hold the caliper in place. On this car, a 2009 Ford Flex, the bolts are on the inside. The arrows in the photograph above point them out. It's generally only necessary to remove the lower bolt. It can be long but once it is fully loosened, it will slide out easily.

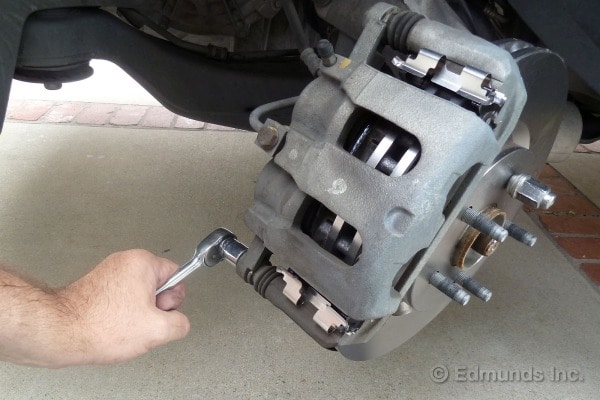

3. With the bottom bolt removed, the caliper pivots up, as shown in the photograph above. The rubber hose, which is the hydraulic line, will flex to allow this so do not disconnect any hydraulic lines. If you think you have to disconnect a hydraulic line, you're doing something wrong. Reassemble the brakes and seek professional help.

At this point, it is very easy to inspect the thickness of the brake pads to confirm that they need to be changed. Most brake pads have metal wear indicators, which are small metal tabs that squeak when they contact the rotors. Even if these are not yet touching, the pads are worn out if the friction material is 1/8th of an inch thick or less at any point.

4. The brake pads are now exposed and the retaining clips hold them loosely in place. Simply slide the old brake pads out, as shown in the photo.

In the above photo, you can see a comparison of the new, thicker brake pad (top), next to the old, worn-down brake pad (bottom).

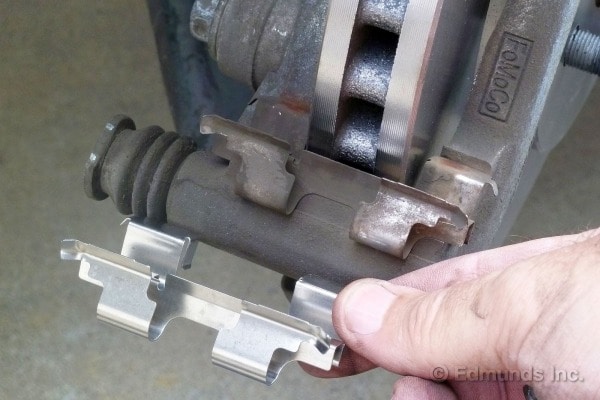

5. The photo above shows the pad's new retaining clips. New pads almost always come with new clips, which allow the pads to slide back and forth easily. Use the new ones and chuck the old ones. There are no retaining screws for the clips. They just snap in place. There are usually left-handed and right-handed clips, so change one at a time, making sure they match up exactly as you go.

Often, a small packet of graphite-based grease will come with the brake pads. Apply this to the clips of the new brake pads to keep them from squeaking, as shown in the photo above.

This photo shows that the new brake pad has a riveted-on shim, which is the thin metal plate. Some brake pads might have unattached shims that have to be temporarily held in position until you lock the pads in place. The "ears" are the metal tabs on either end of the brake pad (only the two left ears are visible here). These ears fit into the slots in the clips. Some of the grease can be applied to the ears and between any loose metal shims, too.

6. The new pads slide into place as easily as the old ones did when they came out, though sometimes the new clips will be tighter. The ears of the new pads should slot nicely into place on the grease you applied.

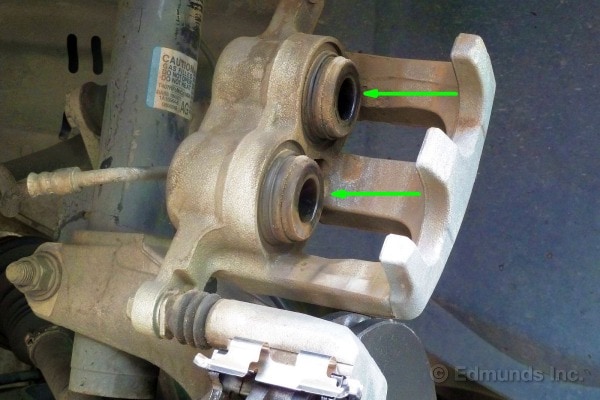

7. In the photo above, the arrows point to the pistons. These pistons press on the brake pads and squeeze the rotor to stop the car. Your car might only have one piston for each wheel, but the principle is the same. Before you can lower the caliper into place, these pistons need to be retracted (pushed back) so that they will clear the new, thicker brake pads.

8. Do-it-yourselfers often use a C-clamp to retract the piston or pistons. In this case, we simply levered the piston back using a 2x4 and a piece of plywood. By doing this, the brake fluid in the pistons is being pushed back into the master cylinder reservoir through tiny passages, so the pistons move slowly. The width of the 2x4 allows both pistons to be pushed in at once. If you pushed in one by itself, the other would pop out — you don't want that. Fortunately, most cars have just one piston per caliper, which makes things far simpler. Either way, steady pressure and patience are key here. In this example, we added a second plywood shim near the end of the process to fill the ever-increasing gap. Throughout, take the utmost care to ensure you don't nick or tear the rubber boot and seal that encircles the pistons.

9. When you push the pistons back, the brake fluid level slowly rises. Open the master cylinder reservoir and check it often. This is more of a concern when you work on the second brake, because the combined fluid volume of two calipers could cause the brake fluid to overflow. If it looks like this is going to happen, suck out some of the brake fluid with a turkey baster. There is more danger of overflowing if someone topped off the fluid level during regular service visits. (This is why the brake fluid reservoir shouldn't necessarily be topped off like that.) The fluid level naturally goes down as the pads wear. And it comes back up when the pads are replaced. As long as the level doesn't go below "MIN," the arrow shown in the photo above, on the lower half of the reservoir, everything is cool.

10. With the pistons retracted, the caliper should slip over the pads with little effort. Sometimes the fit is tight and the caliper will slide on the newly installed brake pads. If the pistons catch on the brake pads, you might need to check that you retracted the piston completely.

11. Reinstall and retighten the slider bolt. Straighten the car's wheels, re-mount the tire and tighten the lug nuts.

12. Repeat all these steps for the other side of the front brakes. Remember that the brake fluid will be higher in the reservoir now that new pads are installed on one side, so keep your eye on the fluid level as you retract the piston on the other side. The fluid will only rise further the second time around. You don't want it to overflow since the brake fluid is highly corrosive. If it looks as if the fluid will overflow, suck some out with the turkey baster. If the level is below the "MAX" when both sides are done, add fresh fluid to top things off to the line.

13. Test-drive the car under safe conditions to make sure everything is working properly, being especially careful for the first few stops. Be aware that your brake pedal might have a higher engagement point. You will quickly get used to this change. Enjoy using your new brakes knowing there are now thick brake pads to stop you safely.

No comments:

Post a Comment